Suzhou FCE precision electronics Co., LTD

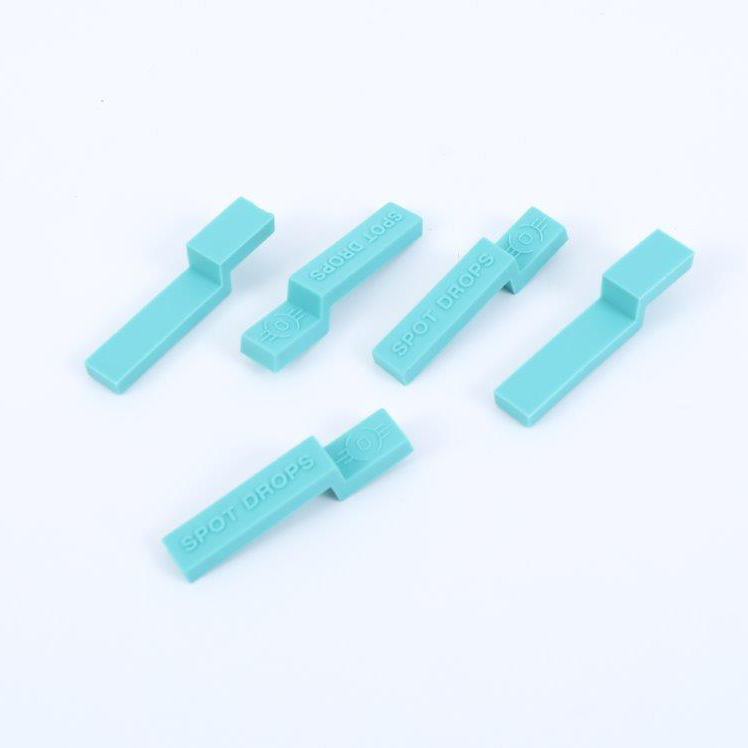

Rubber Compression Molding,Silicon Rubber Molding Fabrication,Phone Cover Colorful Hardness

Suzhou FCE precision electronics Co., LTD

Rubber Compression Molding,Silicon Rubber Molding Fabrication,Phone Cover Colorful Hardness

| Unit Price: | 0.05~1 USD |

|---|---|

| Payment Type: | L/C,T/T,Paypal,MoneyGram |

| Incoterm: | FOB,EXW,CIP,DDP,DDU,Express Delivery |

| Min. Order: | 1 Piece/Pieces |

Brand: FCE

Forming Method: Compression Mould, Plastic Injection Mould, Plastic Extrusion Mould, Extrusion Mould, Blowing Mould, Silicone Mould

Product Material: Rubber, Plastic, Steel, Aluminium, Iron, Copper

Product: Vehicle Mould, Household Appliance, Household Product

Shaping Mode: Plastic Injection Mould

Brand Name: Fce

Hot Runner Brand: Husky/Incoe/Yddo/Hasco/Dme Or Per Required

Surface Finish: Sand Blasting/Texture/Mt/Ys/Spi Polish/Edm Finish

Surface Treatment: Laser-Quenching/Coating By Tic/Zrn/Crn/Mos2/Tialn/Tin-Aln/Cnx/Dlc

Biggest Part Size: 1500*1000mm*1000mm

Material: 45#, 50#, P20, H13, 718, 2738, Nak80, S136, Skd61 ...Etc.

Moldase: Lkm, Hasco, Dme, Futa Or Per Required

Mold Life: 0.5 ~1 Million Shots

Certifications: Certifications:

CAD Format: Recommend Step/Stp/Igs/X-T/Stl/Cad/Pdf/Dwg

Lead Time: 30~35days

Place Of Origin: Jiangsu, China

Packaging: 1-Surface coated with anticorrosive paint 2-Wrapped with PE film 3-Fix the tool into wooden box by screw and customized tool 4- hydraulic cylinder is protected by customized bracket 5- Print basic goods info. Out of box

Productivity: 10000pcs/week

Transportation: Express,Ocean,Land,Air

Place of Origin: China

Certificate: IAO9001 IATF16949

Port: Shanghai/Ningbo/Shenzhen/Other Sea Port In China

Payment Type: L/C,T/T,Paypal,MoneyGram

Incoterm: FOB,EXW,CIP,DDP,DDU,Express Delivery

Compression Molding process is based on the characteristics of each stage of the curing reaction of thermosetting plastics or other moulding materials.

Compression mold uses a hydraulic press in which a mold is fixed on the top and bottom platens of the press. The molds can be classified as hand molds, used for trial runs; semiautomatic, in which the press follows a programmed cycle but the operator manually loads and unloads the press, and automatic, which operate under a fully automatic press cycle (including automatic loading and unloading).

Advantages

Inexpensive Tooling – The low cost of tooling is one of the advantages of compressed molding that everyone appreciates. Without a transfer cycle or injection process, there is not much infrastructure involved. Therefore, tooling costs are significantly less compared to other rubber manufacturing methods.

Ideal for Small Runs – Another benefit is that this method is ideal for small production runs. A lower capital cost for manufacturing a mold tool is the reason behind this.

Perfect for Larger Parts – Compression molding of rubber is also great for manufacturing larger parts and components. Due to the fact that the material loads directly into the mold cavity, there are no restrictions as to the weight of the finished product. The difference between compression molding vs Injection Molding is that with the latter, the barrel can only be filled to a certain volume, which limits the weight of the part of component manufactured.

No Runners, Gates, or Sprues – Another advantage of compressed molding is that no tooling features are required through which the material has to pass, including runners, gates, or sprues. As a result, less material is wasted, there are fewer cosmetic distractions, and the cost is reduced.

0x800x500mm 0x800x500mm | |

| Product material | NR, NBR, SBR, EPDM, IIR, CR, Silicone rubber...etc. |

| Product colors | Pantone code or to sample |

| Prototype tool L/T | 5days for a typical size 150x100x5mm product |

| Production tool L/T | 20days for 20cavity/100x80x10 parts |

| In house 2nd process | Pad Printing/screen printing/painting/laser engraving/coating |

| Payment terms | 50% deposit,50% balance before delivery |

| Shipment | Per customer request |

Product Categories : Rubber Moulding > Compression Molding