In recent years, with the continuous progress of technology and the popularization of electronic products, injection molded plastic, as an important material, has played an important role in the manufacturing of electronic products. Its excellent insulation performance, high temperature resistance, voltage resistance, anti-static and fire resistance make it an ideal choice for electronic product casings, sockets, wire interfaces, circuit boards, etc. Against the backdrop of current hot topics, the application of injection molded plastics is helping the high-tech industry to reach a new level. Firstly, the application of injection molded plastics in electronic product casings continues to innovate. With the rapid development of electronic products such as smartphones and tablets, the requirements for shell materials are also increasing. Injection molded plastic has become the preferred material for manufacturing high-end electronic product shells due to its lightweight, sturdy, wear-resistant, and corrosion-resistant characteristics. At the same time, injection molded plastics have strong plasticity and can be made into various shapes and structures according to product design requirements, meeting the personalized needs of different electronic products. Secondly, the application of injection molded plastics in electronic product sockets and wire interfaces is becoming increasingly widespread. Sockets and wire interfaces are indispensable parts of electronic products, and their quality and performance are directly related to the safety and stability of the product. Injection molded plastic has good insulation performance and voltage resistance characteristics, which can effectively prevent problems such as current leakage and circuit short circuits, and improve product safety. In addition, injection molded plastics also have anti-static properties, which can reduce the interference of static electricity on electronic products and improve product stability and reliability. Once again, the application of injection molded plastics in electronic product circuit boards has also received much attention. Circuit boards are a crucial component in electronic products, directly affecting the performance and functionality of the product. Injection molded plastic has the characteristics of high temperature resistance and fire resistance, which can effectively protect circuit boards from external environmental influences, improve product stability and reliability. At the same time, the processing technology of injection molded plastic is flexible, and precise Injection Molding can be carried out according to the complexity of the circuit board, improving the production efficiency and quality of the product. Against the backdrop of current hot topics, the application of injection molded plastics not only promotes innovation and upgrading of electronic products, but also contributes to the development of high-tech industries. With the rapid development of 5G, artificial intelligence, Internet of Things and other emerging technologies, injection molding plastics have a broader application prospect in electronic product manufacturing. In the future, with the continuous progress of technology and the continuous growth of market demand, injection molded plastics will continue to play an important role in providing higher quality, safe, and reliable material support for electronic products.

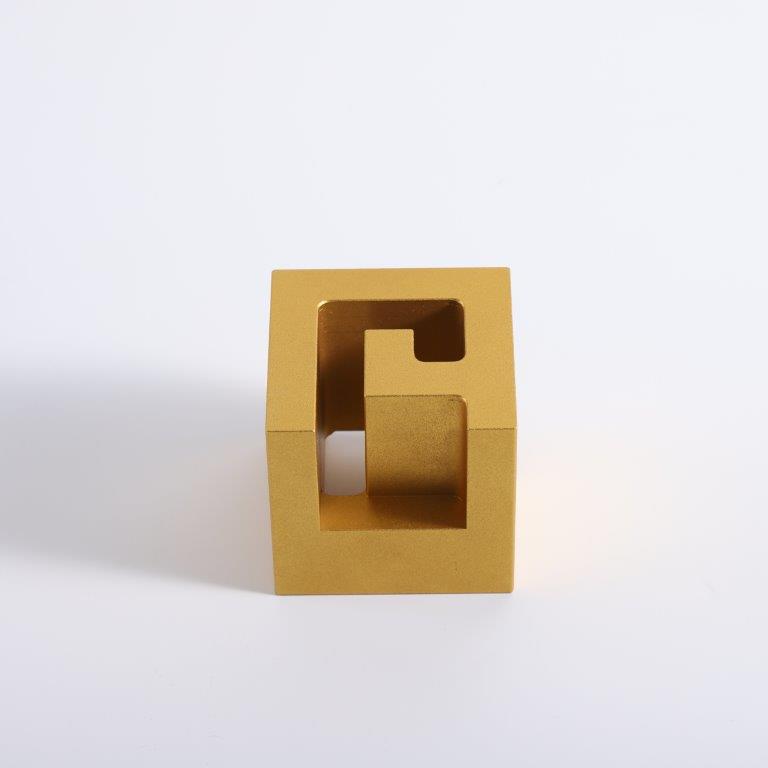

CNC Milling, Cnc Milling , Custom Machining, Injection Molding, Laser Cutting, Molding Services, Multi-K Injection Moulding, Plastic Injection, Powder Coating